Polymers

A thermoplastic polymer created in a process that combines pressure and temperature. Process control determines the density of the polyethylene. High Density Polyethylene improves mechanical strength, abrasion and scratch resistance, tensile strength and heat resistance, chemical resistance and more.

Polyethylene foam (PE foam / PEX / XLPE) is a high-density polyethylene polymer in the structure of closed cells known as the PALZIV brand. Characteristics: Low weight, good buoyancy, fluid tightness, elasticity and elasticity (prone to rest), touchable, heat insulated, shock resistant.

The material is very common because of its low price and its versatile properties. It is used for shrink packaging, plastic bags, piping, bottles, large and small containers and toys.

Laser cutting of Polyethylene

PE foam comes in a variety of thicknesses, compressions and colors. It can be efficiently cut by laser, but it recedes slightly during the cut (KERF is relatively wide). Another effect is slightly darkened edges as a result of the laser beam. When preparing the files for laser cutting, consider that the dimensions after the cut will be slightly different in relation to the drawing. The thicker the material, the greater the width of the incision.

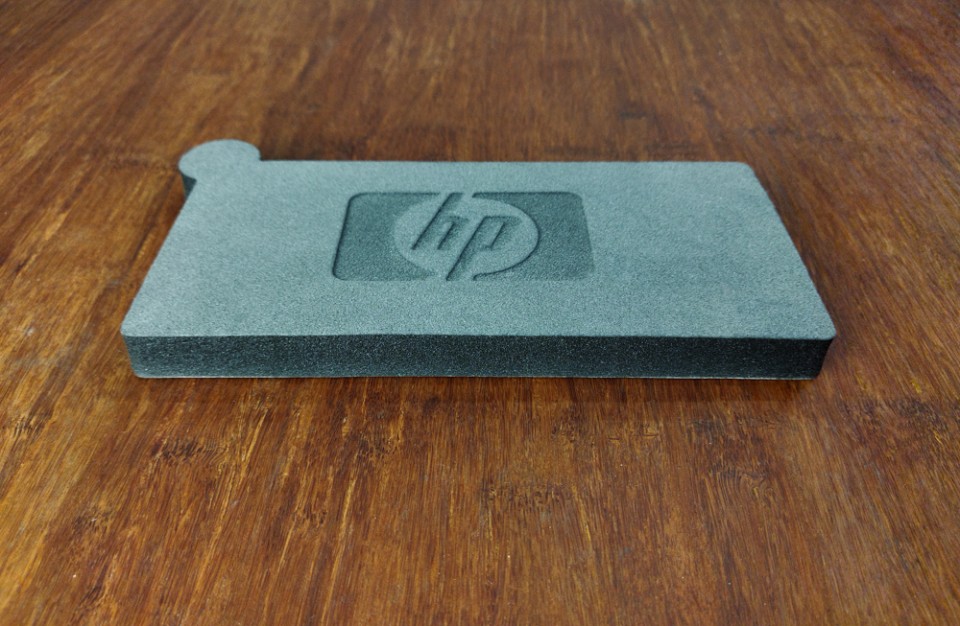

Laser engraving of Polyethylene

The material can be engraved resulting in darkened surface, but is more suitable to area than to fine text and small details. It can also produce mark lines and create slots to help bending the material.

Applications - Sports and surfing equipment, packaging, toys, buoys, pool equipment, special promotional products etc.

For a quote - Press Here!