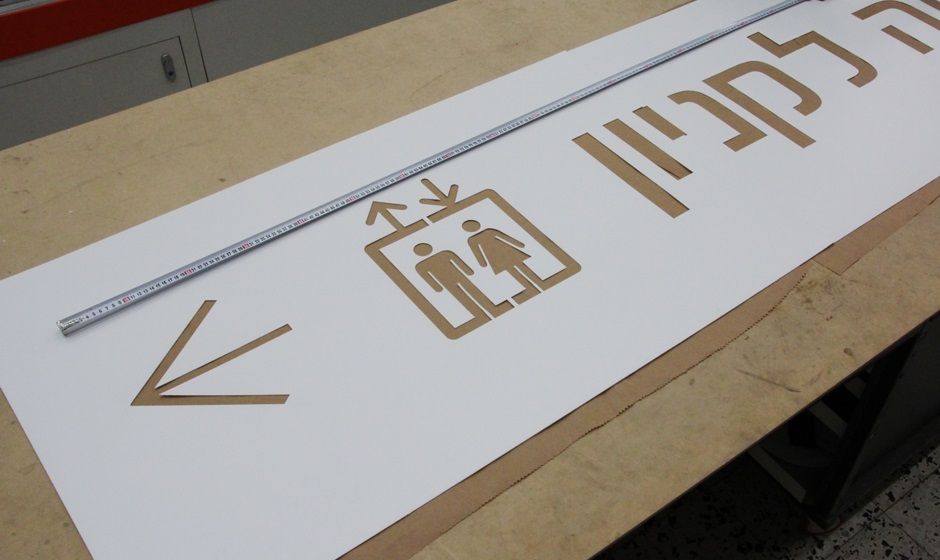

Laser cutting of stencils

Laser cutting of a multi-time painting stencil made o stainless steel

What is a Stencil for painting?

A paint stencil is a kind of mask that allows you to apply paint on any substrate, accurately and according to per-designed graphics. It allows quick and accurate work. A suitable stencil allows you to repeat the painting as many times as necessary. Similarly, you can use it for applications other than painting, such as applying a precise adhesive that can be repeated over and over again.

More Examples of Laser cutting stencils

What is a stencil made of?

In fact, it is possible to produce stencils from almost any sheet which can be cut with a laser. However, there are several more suitable materials. In the following list you can find the main materials that are suitable for creating a template using laser cutting:

- Paper - a cheap and available material that is accurately and quickly cut off by laser, but absorbs color and is characterized by rapid wear. Paper stencils are suitable for single use. Here are some other Examples of Laser cutting of paper.

- Sticker paper - similar in its properties to paper, but thanks to the adhesion, a good linkage is made to the surface on which the paint / glue is applied, and the result is very accurate. It is highly recommended to use this stencil when applying paint / glue to cylindrical bodies, such as coloring on a page.

- polyester (Mylar) - A thin polyester sheet that looks like a piece of paper, but is not absorbent and therefore very suitable for creating a mold for repeated use. The Mylar is cut in a very fast and accurate way, which gives a quality template with detailed and accurate graphics at a relatively cheap price. The strength of the Mylar relative to its thickness (less than one tenth of an inch) gives it durability and versatility.

laser cutting of a large format stencil for painting of a parking lots- Polypropylene (PP) - a plastic sheet that comes in a variety of thicknesses, common in the range of 0.3 mm to 1.0 mm. The material is very flexible and therefore durable and suitable for repeated uses. The material is limited in cutting a very detailed graphics due to the fact that it is tend to melt in close proximity between cutting areas. Because of these features, it is highly recommended to use a polypropylene foil when the graphics are not too detailed and there is a need for reuse. Here are some other Examples of Laser cutting of polypropylene.

- Acrylic (PMMA) - is a relatively high quality plastic that can be obtained at a thickness of 2 mm or more.The acrylic laser cutting is very precise and due to its thickness and elasticity, it is suitable for creating rigid stencils for repeated use. Acrylic is expensive in relation to other materials. Here are some other Examples of Laser cutting of Acrylic.

- Cardboard - Various cardboard and cartons can be cut in laser, but the most suitable for making stencils are the high density cardboard. cardboard has similar properties to paper, but due to its thickness, a certain stiffness and durability is added. Cardboard is a relatively cheap material and the cost of laser cutting it is relatively low. Here are some other Examples of Laser cutting of Cardboard.

- Rubber and silicone - flexible and durable materials that can be cut with laser to produce stencils for a variety of uses. Silicone is a material with a very high friction coefficient, which clings to the glass in a good way even without adhesive and allows convenient and multi-time work. Here are some other Examples of Laser cutting of Silicone and Rubber.

- Magnet - It is possible to produce a stencil of a magnetic sheet thickness of about 0.5 mm which enables good adhesion to iron surfaces which helps painting columns, curved surfaces, etc. Magnetic Stencil allows good adhesion to hard surfaces such as ceilings or low accessibility areas.

Remarks:

- The lower the thickness of the tab, the more precise the detail can be obtained.

- we can not laser cut PVC (polyvinyl chloride) because it emit toxic gases during cutting.

What are the main uses that need to be used?

- Painting of children's rooms.

- Educational toys for children - Tools for drawing various basic shapes.

- Draw letters and numbers - contour or full letters.

- graffiti art.

- Kids activities.

- Creating signs for advertising and / or guidance.

- Branding of products and packaging.

- Performing art and creative works.

A letter stencil cut with laser technology for drawing with a pencil

A letter stencil cut with laser technology for drawing with a pencil

What are the advantages of laser cutting stencils?

- The freedom to produce custom stencil by any shape and graphics.

- Ability to produce complex and detailed graphics.

- Achieving great accuracy according to computerized drawing file.

- Ability to use a variety of materials - flexible / rigid, thick / thin, sticky and more.

- Final and high quality finish - the stencil is ready for use immediately after it goes out of the laser machine.

- Fast and cheap production - the production of the template starts once the file is closed, without the need to produce tools and / or templates.

- Use of cheap and available materials.

- Wide range of sizes - from a few millimeters to machine limit (250 cm by 130 cm).

- Replication ability - the ability to reproduce the exact same pattern at any given time.

What are the considerations in planning a stencil?

Stencils are designed for a wide range of applications. In designing the appropriate stencil, we must consider the following factors:

- The nature of the graphic - the level of detail in the template, the density of the artwork, complexity, etc.

- The required strength is derived from both the type and thickness of the material and the graphic structure.

- Way of paint - Spray, roller, brush or sponge.

- Drying time.

- What type of surface are we going to paint - flat or convex? What material is it made of?

- Flexibility of the stencil - for application on concave / convex substrate.

- Durability of the stencil - a one-time or a multi-time stencil.

- Price.

Important to know!

At the time of planning the stancil, internal spaces must be connected to the stencil, for example in letters such as 'O' and 'D' or in digits like '8' and '0', so that the cut area of the signal / digit remains connected to the stencil. There are special fonts for creating stencils, but you can also use regular fonts and make the connections manually using various drawing programs. This, of course, also applies to any graphics that have internal parts that would be cut completely if we did not use this method.

laser cutting of a stencil made of polypropylene for wall painting

laser cutting of a stencil made of polypropylene for wall painting

Stencil or stamp?

In some cases where the graphic is very detailed and weakens the template, especially when it is necessary to repeat painting repeatedly, it is possible to produce a rubber stamp. with laser engraving on specific rubber we can produce precise and complex stampa up to size of an A4 sheet. A rubber stamp allows you to apply any type of graphics and is not limited to text alone. This stamp has great durability it is fast and convenient to use.