Cutting, Engraving and marking with Laser

Laser Engraving

Laser Engraving is a process in which the Laser beam hits and mark the surface of the material and actually erodes or evaporates a layer of material according to a designed graphic file, which defines the areas to be engraved by objects and enclosed areas, usually in full color. In this way, it is possible to engrave in a vector form, that is, along lines that appear in the drawing, or by covering an area that is enclosed in a graphic form, which takes a longer time than linear writing. Controlling the speed settings and the intensity of the laser beam will determine the type of marking: the depth, the density, the accuracy, and more.

Laser engraving on maple wood - a logo added to a guitar bridge for branding manners

Laser Marking

The laser marking process is similar to the engraving process while the power intensity and time settings are similar.

Unlike engraving, the nature of the graphic is different and instead of a full areas to be filled with the laser etch, we will refer to lines (vector only). The process of marking is faster than the engrave process, since the number of lines the graphics are made of is usually smaller than with area shapes, and the speed of the machine is close to the maximum speed as the power is sufficient to perform the etch.

Materials suitable to Engrave on:

Unlike a pattern, in which color is added to the product and variable color graphics can be selected, the process of burning or engraving is a process of texturing and material etching and in this process no colors or pigments are added. The appearance of the graphic is obtained from a change in the surface clarity of the material between the areas that were etched and the material raw surface.

In special materials that are not in stock, it is necessary to check the behavior of the material by doing a test, since any material response differently to the laser beam.

Laser Engraving of barcode on an anodized aluminum label

Laser Engraving of a QR barcode on double-layer ABS plastic

More useful Information:

- Lines or areas - the nature of the work affects the cutting time. engraving areas relative to lines means a longer working time.

- Appropriate file - set a different line color For entities to be engaved. all areas should be set in a closed curve.

- Type of material - Deep engraving affects the working time in soft materials. This can be done quickly, and with hard materials a little less quickly.

- The overall size of the job - the working area affects the working time. as a rule, Large area = larger working time.

- The result - different results are obtained in different materials. Each engraving in each material looks different, so attention must be paid to the needed result.

to see our stock of materials for laser cutting, laser engraving and laser marking, click here.

Laser cutting and engraving of advertising product illuminated with LED lighting

laser cutting and laser engraving combination

Sometimes we prefer to produce a laser product that will consist of both engraving and cutting. In this case, the drawing file must be supplied in two colors. Lines in one color will define the cutting part and the area to be engraved with another color. this why tha Laser machine will preform acording to the parameters we choose for each color.

It is important to remember that the engraving stage precedes the cutting phase (in the same run) in order to maintain the position of the etched areas relative to the cutting lines of the product.

More and more Laser cutting products are taking place on the shelves of many stores and many of them madeof materials such as acrylic, wood, paper and more.

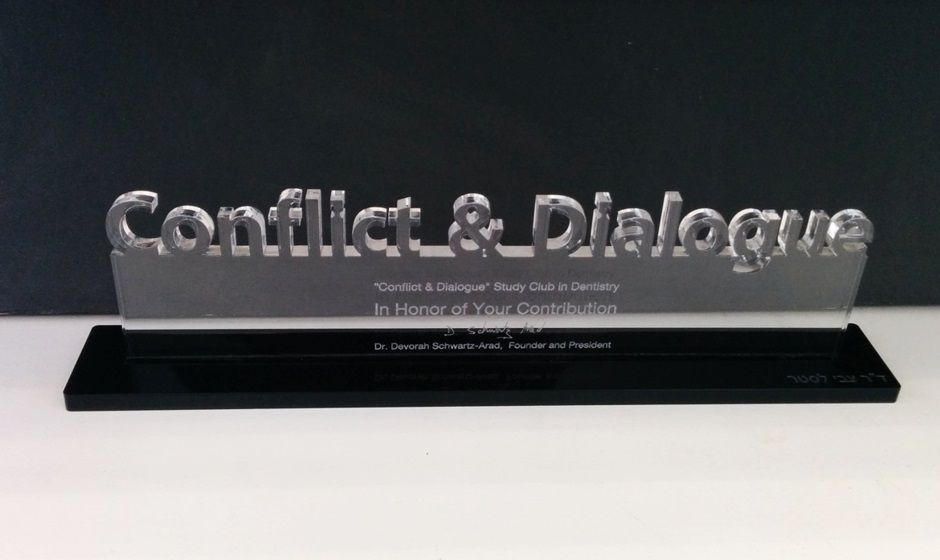

A combination of laser engraving and laser cutting - a transparent acrylic reward