Laser cutting of Acrylic - all you need to know

What is acrylic glass (Perspex)?

Acrylic glass, also known as PMMA, is a plastic material (synthetic polymer), widely used both for industry and for domestic use. The scientific name of acrylic glass is methacrylate-polymethyl.

Acrylic can be found in a wide range of products and in a vast range of fields such as: The furniture industry, aviation (the windows of the airplane and cockpit), in the feld of computing and electronics (CDs, DVDs, electronic panels), used by industrial designers and jewelry designers, as well as medicine, pharmaceuticals and research laboratory equipment.

Many people know the acrylic glass by its trade names, which have become almost synonymous with perspex, plexiglas, acrylite, acrylast, acrylic and more.

Acrylic properties are:

- High Transparency - Moves more than 90% of visible light (more transparent than glass).

- Hardness and brittleness - relative to glass, resistant to impact without crashing, broken by bending.

- Low density - Specific weight is lower than glass.

- Good UV resistance - Used in outdoor signs.

Plexiglas is thermoplastic and can be flexed and shaped using heat, either by simple bending devices that enable bending of perspex along stright lines or by using specialized ovens and 3D molds that determine the final shape of the material.

Laser processing of acrylic board

Plexiglas can be processed using a laser beam in two ways:

- Laser Cutting of Plexiglass - Plexiglas can be cut efficiently, fast and clean. The cutting is done using material sheets placed in the laser machine, and cut according to a computerized drawing file prepared in advance by the designer. The finish is in a very high quality and does not usually require further processing. The cut line is obtained relatively clean and polished with no fire and soot. At Lasercut4 we can be cut Perspex up to 20 mm thickness

- Laser engraving of Plexiglas - Plexiglas plates can be engraved accurately. The engraving is performed on the surface of the material, but may also reach depths of a few millimeters (depending on the laser power). The process does not include the addition of pigments or paint. The result is a change of the surface texture in relation to the raw material face (in sheets manufactured by casting process , the engraving on the surface looks as a white mark). This method can actually mark products, add symbols, logos and / or relevant technical information. In addition, laser cutting can be used to reduce material in a defined area or to adjust dimensions of parts to connect them in a precise way.

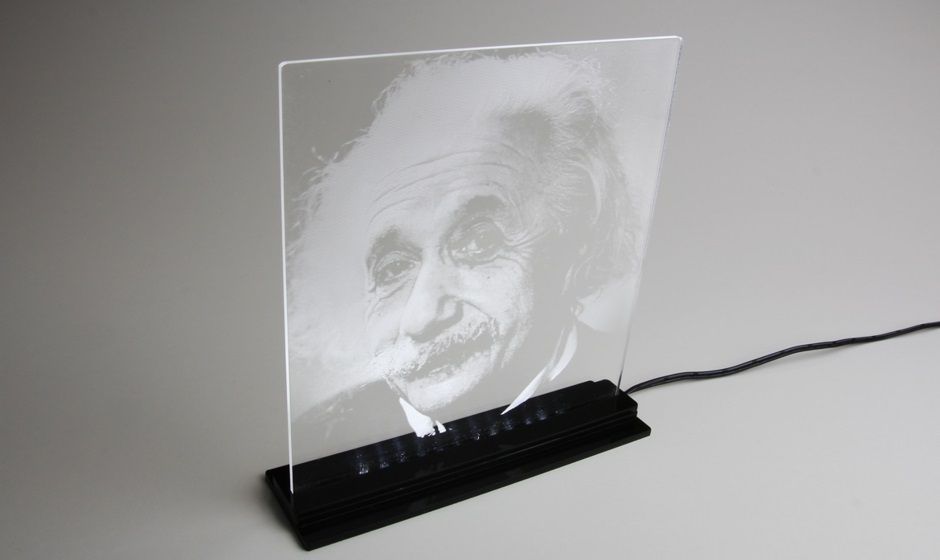

Laser engraving of Acrylic sign - LED illuminated

Acrylic boards are manufactured in two different ways:

- Extrusion - A method in which the board forms from the transition of material in molten state through pulleys that shape the thickness and size of the board as it cools and crystallizes back into solid material. A Plexiglas board created in this method is sometimes called an "extruded sheet" in the industry.

- Casting - This method pours the molten material into a mold (between glass plates). The type of the template determines the thickness of the material (there are tolerance variations in thickness in different parts of the panel).

At Lasercut4, we use high quality acrylic sheets of leading brands such as Perspex, as well as other European quality brands. Plexiglas comes in a variety of thicknesses and colors and is very homogenous, so uniform color at each point in the material.

Common uses of Perspex

Plexiglass products are all around us everywhere we look. From display stands for jewelry, catalog sets made of Perspex, Clear Plexiglass display units, Acrylic promotional products and more.

The use of Perspex for these products is very common due to the good and rapid processing capabilities of Plexiglas with the laser technology, the finish level, the quality obtained, and the ability to plan, design and provide a customized solution for every need in the marketing.

Plexiglass is often used as an alternative to glass due to its properties and advantages relatively to glass: high transparency, fraction resistant, low weight and price.

Other Perspex products: clear and transparent shelves, wall coverings and table covers, special packaging, custom key chains, plexiglass stencils, models, signs and more.

Acrylic backlight (LGP) lighting fixtures

The optical properties of the Acrylic board, which enable good and unobstructed light transmission, are used in lighting fixtures and lighting panels, known as backlight.

A backlight panel is a plexiglass board that is normally lit by a light source (usually by LEDs) on one or more sides of the material, and illuminates relatively uniformly across the surface of the board. The illumination effect is created by the engraving (hatch) of the board to break the light passing through the clear material towards the viewer's eyes. The intensity of the illumination varies according to the depth of the engraving, and by changing the settings and direction of the laser intensity, a uniform lighting effect can be produced on the entire board. You can also control the burned graphics to produce illuminated signs, including text, logos, or any desired graphics. You can use light sources of different colors and even alternating colors to get different effects and mood lighting.

Laser engraving of image on acrylic illuminated by LED light